Description

• Steel storage tank, thickness 3 mm, made of butt-welding process, outer enclosure made of ABS resistant to scrapes and shocks. Inner coating according to DIN 4753.3. Thermal insulation in PU polyfoam, thickness 50 mm, granting minimum density 40 Kg/m3.

• Hydraulic fittings on the left side of the product (on the right access for the anode replacement).

• Integrated condensate drain.

• Condenser externally wrapped around the tank, designed to prevent risks of fouling and gas-water contamination.

• Automatic defrosting through “hot gas”.

• Integrated NTC sensors to control the water temperature.

• External air temperature sensor for the automatic resistance switch-on when the external air temperature (< -6°C), is not suitable for heat pump operation.

• Magnesium sacrificial anode.

• Power of electrical resistance 1.5 kW.

• Safety devices against the risks of high pressure in the refrigerant circuit.

• Quiet and efficient hermetic rotary compressor, working with environmental friendly gas R134a.

• Centrifugal backward curved fan moved by an EC (brushless) motor.

• Electronic suite integrating a control panel with keyboard and LCD display, for self-diagnosis (high pressure, water overheating, disconnected probes) allowing to control machine functioning and setting modes. Access for settings protected by password.

Through the electronic is possible to:

• Set the water temperature,

• Handle the integrated electric resistance during Eco or Boost operation modes.

• Automatically start the antibacterial treatment aimed to prevent risks of legionella contamination.

• Schedule the product automatic switching on/off, to reduce the energy power consumptions.

• Show error messages.

• Show the in-progress defrosting cycle.

• Show the filter status.

• Hydraulic fittings on the left side of the product (on the right access for the anode replacement).

• Integrated condensate drain.

• Condenser externally wrapped around the tank, designed to prevent risks of fouling and gas-water contamination.

• Automatic defrosting through “hot gas”.

• Integrated NTC sensors to control the water temperature.

• External air temperature sensor for the automatic resistance switch-on when the external air temperature (< -6°C), is not suitable for heat pump operation.

• Magnesium sacrificial anode.

• Power of electrical resistance 1.5 kW.

• Safety devices against the risks of high pressure in the refrigerant circuit.

• Quiet and efficient hermetic rotary compressor, working with environmental friendly gas R134a.

• Centrifugal backward curved fan moved by an EC (brushless) motor.

• Electronic suite integrating a control panel with keyboard and LCD display, for self-diagnosis (high pressure, water overheating, disconnected probes) allowing to control machine functioning and setting modes. Access for settings protected by password.

Through the electronic is possible to:

• Set the water temperature,

• Handle the integrated electric resistance during Eco or Boost operation modes.

• Automatically start the antibacterial treatment aimed to prevent risks of legionella contamination.

• Schedule the product automatic switching on/off, to reduce the energy power consumptions.

• Show error messages.

• Show the in-progress defrosting cycle.

• Show the filter status.

Technical Data Sheet

-

Frequency (Hz)50

-

Full load weight240

-

IPX4

-

Mean absorbed electric power (W)430

-

Net weight70

-

Power of integrated electric heater (W)1,5

-

Refrigerant charge (g)900

-

Refrigerant gasR134a

-

Tank capacity (l)160

-

Thermal power at pump side (W)1.820

-

Voltage (V)230

-

Weight (Kg)75

-

Anti-legionella system (at 70 °C)Automatico

-

Max water pressure7

-

Max water temperature38

-

Min water temperature-7

-

Nominal air flow rate350 / 500

-

Operation modeAuto-Eco-Boost

-

Warming time (EN 16147:2011)6:34

-

Warming time in Boost mode (EN 16147:2011)3:08

-

Dimension Q (mm)535

-

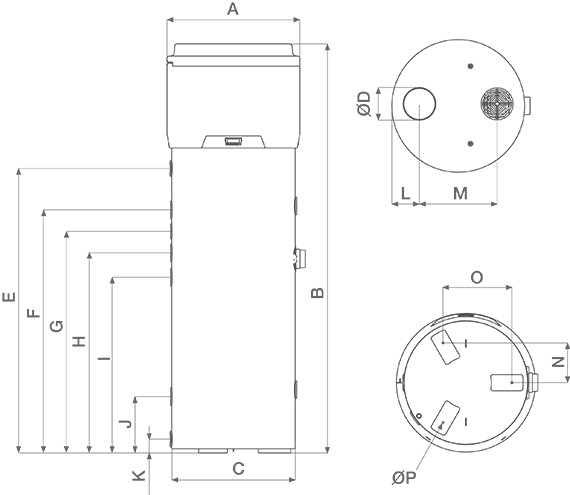

Size A (mm)Ø 650

-

Size B (mm)1504

-

Size C (mm)Ø 600

-

Size D (mm)Ø 160

-

Size E (mm)891

-

Size G (mm)670

-

Size I (mm)590

-

Size J (mm)275

-

Size K (mm)70

-

Size L (mm)150

-

Size M (mm)380

-

Size N (mm)195

-

Size O (mm)337,5

-

Size P (mm)Ø 10

Interested?

If you are interested in this product, contact us or locate your nearest Vortice dealer.

Documentation

You can see all the documentation relating to this product: price list, information booklet and wiring diagram.