Description

• Frames consisting of rounded aluminium profiles with built-in, polyamide made, spacers for class TB2 thermal break; corners made of reinforced polyamide; double skin (sandwich), 10/10 panels (inner side with galvanized steel sheet, outer side with pre-laquered metal sheet (RAL 7035) with protective film); insulation through 50 mm high density (M0) mineral wool.

• 2 EC motors, independently adjustable, external rotor type, integrating safety thermal cut-outs, with backward curved impellers directly driven by ball bearings; 2 speeds adjustable during the installation.

• Air-to-air, counter cross-flow, aluminium made heat exchanger whose high performance, certified by Eurovent, exceeds 90% according to EN 308 standard.

• Automatic pre-heater.

• Circular branch connections with lip seals to grant the system air tightness.

• 100% inner automatic by-pass.

• 2 filters, respectively G4 on extracted air (stale) and F7 on (fresh) air supply, both mounted upstream of inner components, on runners fitted with lip seals to ensure effective air tightness.

• Access to filters and inner components by security latch on removable panels.

• Inner slanted tray to assure the proper condensate removal at product horizontally installed.

• Advanced electronic control suite, including a control box enriched by a LCD display allowing:

o To independently adjust the fan speeds,

o To modulate the opening of the by-pass,

o To set a weekly, holiday and public holiday timer,

o To control the status of both filters,

o To integrate the unit in a BMS (communication protocols supported are MODBUS, BACNET and WEB TCP-IP),

o To set the unit operation mode in case of fire, to be allowed among 5 pre-defined fan control alternatives,

o The machine diagnostic.

• A podlockable local circuit breaker, mounted on front panel, allows to stop the unit in case of fault.

• 2 EC motors, independently adjustable, external rotor type, integrating safety thermal cut-outs, with backward curved impellers directly driven by ball bearings; 2 speeds adjustable during the installation.

• Air-to-air, counter cross-flow, aluminium made heat exchanger whose high performance, certified by Eurovent, exceeds 90% according to EN 308 standard.

• Automatic pre-heater.

• Circular branch connections with lip seals to grant the system air tightness.

• 100% inner automatic by-pass.

• 2 filters, respectively G4 on extracted air (stale) and F7 on (fresh) air supply, both mounted upstream of inner components, on runners fitted with lip seals to ensure effective air tightness.

• Access to filters and inner components by security latch on removable panels.

• Inner slanted tray to assure the proper condensate removal at product horizontally installed.

• Advanced electronic control suite, including a control box enriched by a LCD display allowing:

o To independently adjust the fan speeds,

o To modulate the opening of the by-pass,

o To set a weekly, holiday and public holiday timer,

o To control the status of both filters,

o To integrate the unit in a BMS (communication protocols supported are MODBUS, BACNET and WEB TCP-IP),

o To set the unit operation mode in case of fire, to be allowed among 5 pre-defined fan control alternatives,

o The machine diagnostic.

• A podlockable local circuit breaker, mounted on front panel, allows to stop the unit in case of fault.

Technical Data Sheet

-

Filter class on extractG4

-

Filter class on supplyF7

-

Frequency (Hz)50

-

Max ambient temperature for continuous operation (°C)50

-

Min continuous operation room temperature (°C)-20

-

Motor classB

-

Motor power (W)1950X2

-

Motor protection IP54

-

Nominal diameter (mm)630

-

Number of phases (Ph)3+N

-

Pre-heater power18,00

-

Protection current32,3

-

Voltage (V)400

-

Weight (Kg)727

-

Breakout sound power LWA [dB(A)]60

-

Max airflow (m³/h)6500

-

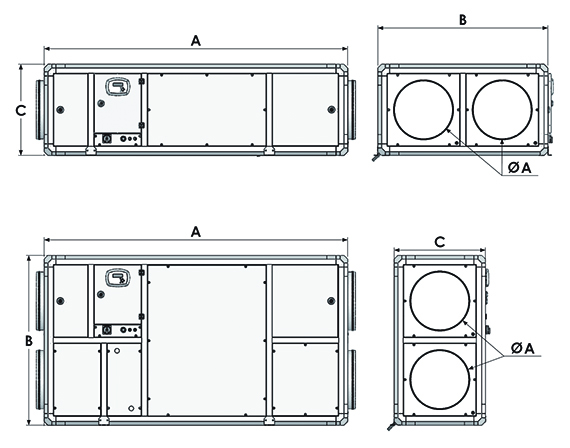

Size A (mm)2970

-

Size B (mm)1715

-

Size C (mm)1030

-

Size D (mm)455

-

Size E (mm)805

-

Size J (mm)645

-

Size K (mm)840

-

Size T (mm)1/2"

-

Vent diameter Ø A (mm)630

Interested?

If you are interested in this product, contact us or locate your nearest Vortice dealer.

Documentation

You can see all the documentation relating to this product: price list, information booklet and wiring diagram.