Description

• Centrifugal roof fan suitable for extracting hot fumes at up to 400 °C for 120 minutes.

• Base manufactured from phosphated pressed steel, epoxy powder coated with hammered effect finish, guaranteeing long-term resistance to atmospheric agents.

• Aerodynamically contoured inlet port for optimum performance, fashioned as a single unit with the base and gauged to optimize air flow.

• Motor mounting plate made of steel with galvanization surface treatment.

• Protective cap carried by top plate made of steel with galvanization surface treatment.

• Cold outside air drawn into a cooling chamber made of pressed steel with polyester powder coated and oven baked hammered effect finish, colour grey.

• Pressed steel motor cover: pickled and phosphated surface, polyester powder coated and oven baked finish, colour grey, with hammered texture.

• Accident prevention and anti-bird grilles (to UNI ISO 13857 standard), consisting of electrically welded steel rings with epoxy powder coated finish, colour black.

• Centrifugal impeller with self-cleaning backward curved blades, dynamically balanced (UNI ISO 1940, Point 1 – Class 6.3), made of electrolytically galvanized steel.

• Dahlander 2 speed three-phase AC motor with shaft turning in ball bearings, size to UNEL MEC standard, flange B5, self-ventilating. Motor insulation class H, with metal cooling fan and cable gland.

• Minimum air flow 5300 m3/h.

• Maximum air flow: 6000 m3/h.

• Galvanized steel eye lugs for transport and lifting/handling operations.

• Cable guaranteeing continuity of earth connection.

• Steel safety wire for anchoring appliances once installed.

• Vortice speed controller.

• Base manufactured from phosphated pressed steel, epoxy powder coated with hammered effect finish, guaranteeing long-term resistance to atmospheric agents.

• Aerodynamically contoured inlet port for optimum performance, fashioned as a single unit with the base and gauged to optimize air flow.

• Motor mounting plate made of steel with galvanization surface treatment.

• Protective cap carried by top plate made of steel with galvanization surface treatment.

• Cold outside air drawn into a cooling chamber made of pressed steel with polyester powder coated and oven baked hammered effect finish, colour grey.

• Pressed steel motor cover: pickled and phosphated surface, polyester powder coated and oven baked finish, colour grey, with hammered texture.

• Accident prevention and anti-bird grilles (to UNI ISO 13857 standard), consisting of electrically welded steel rings with epoxy powder coated finish, colour black.

• Centrifugal impeller with self-cleaning backward curved blades, dynamically balanced (UNI ISO 1940, Point 1 – Class 6.3), made of electrolytically galvanized steel.

• Dahlander 2 speed three-phase AC motor with shaft turning in ball bearings, size to UNEL MEC standard, flange B5, self-ventilating. Motor insulation class H, with metal cooling fan and cable gland.

• Minimum air flow 5300 m3/h.

• Maximum air flow: 6000 m3/h.

• Galvanized steel eye lugs for transport and lifting/handling operations.

• Cable guaranteeing continuity of earth connection.

• Steel safety wire for anchoring appliances once installed.

• Vortice speed controller.

Technical Data Sheet

-

Frequency (Hz)50

-

Insulation classI°

-

Max absorbed current at Max speed (A)1,30

-

Max absorbed current at Min speed (A)0,90

-

Max absorbed power at Max speed (W)620

-

Max ambient temperature for continuous operation (°C)90

-

Motor protection IP55

-

Nominal diameter (mm)400

-

Number of phases (Ph)3

-

Number of poles6

-

Power absorbed at 1st speed (W)450

-

Voltage (V)400

-

Weight (Kg)131

-

Airflow at 1st speed (l/s)1472

-

Airflow at 1st speed (m³/h)5300

-

Max airflow at Max speed (l/s)1667

-

Max airflow at Max speed (m³/h)6000

-

Max pressure at Max speed (mmH20)38

-

Max pressure at Max speed (Pa)373

-

Max RPM940

-

Min RPM760

-

Pressure at 1st speed (mmH20)30

-

Pressure at 1st speed (Pa)294

-

Sound pressure Lp [dB (A)] at 3 m74

-

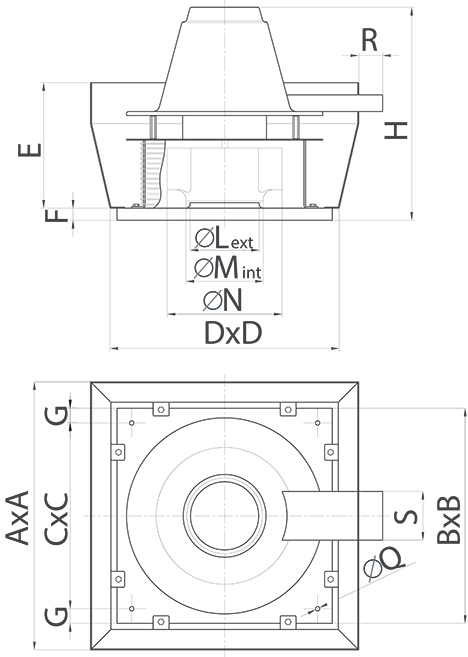

Dimension Q (mm)12

-

Dimension R (mm)50

-

Size A (mm)1144

-

Size B (mm)830

-

Size C (mm)750

-

Size D (mm)860

-

Size E (mm)491

-

Size F (mm)38

-

Size G (mm)40

-

Size H (mm)743

-

Size L (mm)365

-

Size M (mm)375

-

Size N (mm)564

Interested?

If you are interested in this product, contact us or locate your nearest Vortice dealer.

Documentation

You can see all the documentation relating to this product: price list, information booklet and wiring diagram.